Hello everybody, today I am going to give you all a brief introduction to 3D printers: what are they? what do they do? how do they work? and should you think about getting one. Bare in mind I will be keeping this as simple as possible so I wont be going into too much detail regarding brands and some of the technical specifications.

What is a 3D printer?

A 3D printer prints objects using special materials, as opposed to printing on objects such as paper using a normal inkjet/laser printer. 3D printers can print objects using various materials (more on some of those later) such as plastic as opposed to using ink. 3D printers used to be extremely expensive and were only used in specific jobs or by rich enthusiasts, now they can be found for between €200 and €300 in a variety of applications both business and consumer.

How do they work?

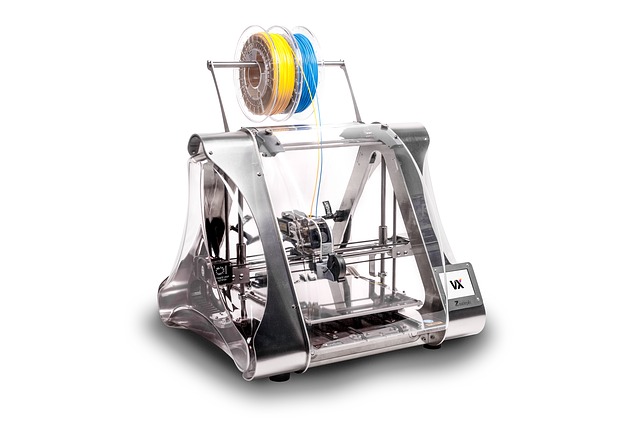

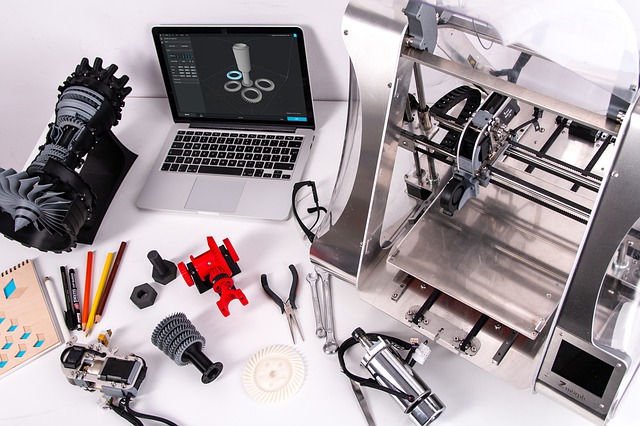

The most common and cheapest type of 3D printer uses spools of material called filament, examples include PLA, ABS (both strong rigid plastics), and TPU (a flexible material used for smartphone cases). This filament is fed into the printer, melted, and quickly “printed” onto a heated platform where it cools almost instantly and hardens. The printer gradually prints the desired object by printing in layers according to preprogramed instructions. These instructions are held in a file that the user must either create themselves or download from a myriad of websites. Once the object is printed the user can use it straight away, or they may decide to paint it themselves, sand down rough edges, or combine it with other objects to create one larger object.

What can it print?

Due to the wide variety of filaments available, almost anything can be printed with constant innovations being made every day in the area. Essentially many everyday objects such as storage boxes for small objects, coat hangers, door handles, mobile phone/tablet cases, headphone hangers, and many more can be printed. On the consumer front, this can make them very handy when it comes to small DIY jobs around the house, or if you need to find a quick and small gift in a hurry. The only real barrier is whether you can find a model online that suits your needs, unless you have the specialist software to design your own objects.

In certain industries more impressive advancements are being made. In medicine scientists are making great progress in printing human organs with the aim of eventually reducing the reliance on organ donors, they are also used to make small medical devices, and fake eyeballs (see this BBC article). In manufacturing, replacement parts for machines and even small parts of products are being 3D printed especially if a custom size is needed.

Since the creation of 3D printers, innovators have been trying to use them to print food that is edible and familiar. They have made great progress on this front especially when it comes to meat, with many companies popping up trying to find ingenious ways of printing something that both looks and tastes like the real thing with special filaments being the key to this.

Do I need one?

In short, no. The long answer is that if you have the money, the need (business or otherwise), and the ability to learn how to maintain one, then go for it. I do think that when the 3D food printers are advanced enough a wider audience will almost have to have them, but there are still some barriers to that. The first applies to all cheaper 3D printers, and that is their slow print speed, especially if the food must be cooked afterwards. Some smaller non-food objects already take 4 hours to, so having to wait longer than that for the “raw” food to print, only to have to spend more time cooking it, may make it easier to simply buy the food in a supermarket instead. The second barrier is the moderate technical knowledge requirement that such a device would require; my guess, however, is that the manufacturers of such devices will realise this and make such barriers lower for the machines in the next few years, but this could increase costs for the consumer.

Conclusion:

So, to conclude, I do think 3D printers will find a place in people’s homes in the next 10-20 years. Provided the technology improves at the same rate it currently is, I could see a 3D food printer in many kitchens once they overcome those barriers mentioned above, and if the technology becomes sufficiently user friendly, they might even replace vending machines in some places. For the moment however, I think the focus should be on their medical applications as this could greatly improve, and even save lives especially when used to print replacement organs. So, to reiterate, no you do not need one, but if you are tech savvy enough, give it a go, get a glimpse into the future as you may see more of them in the next few years.

As always if you have any suggestions for future content leave them in the comments either here or on Facebook.